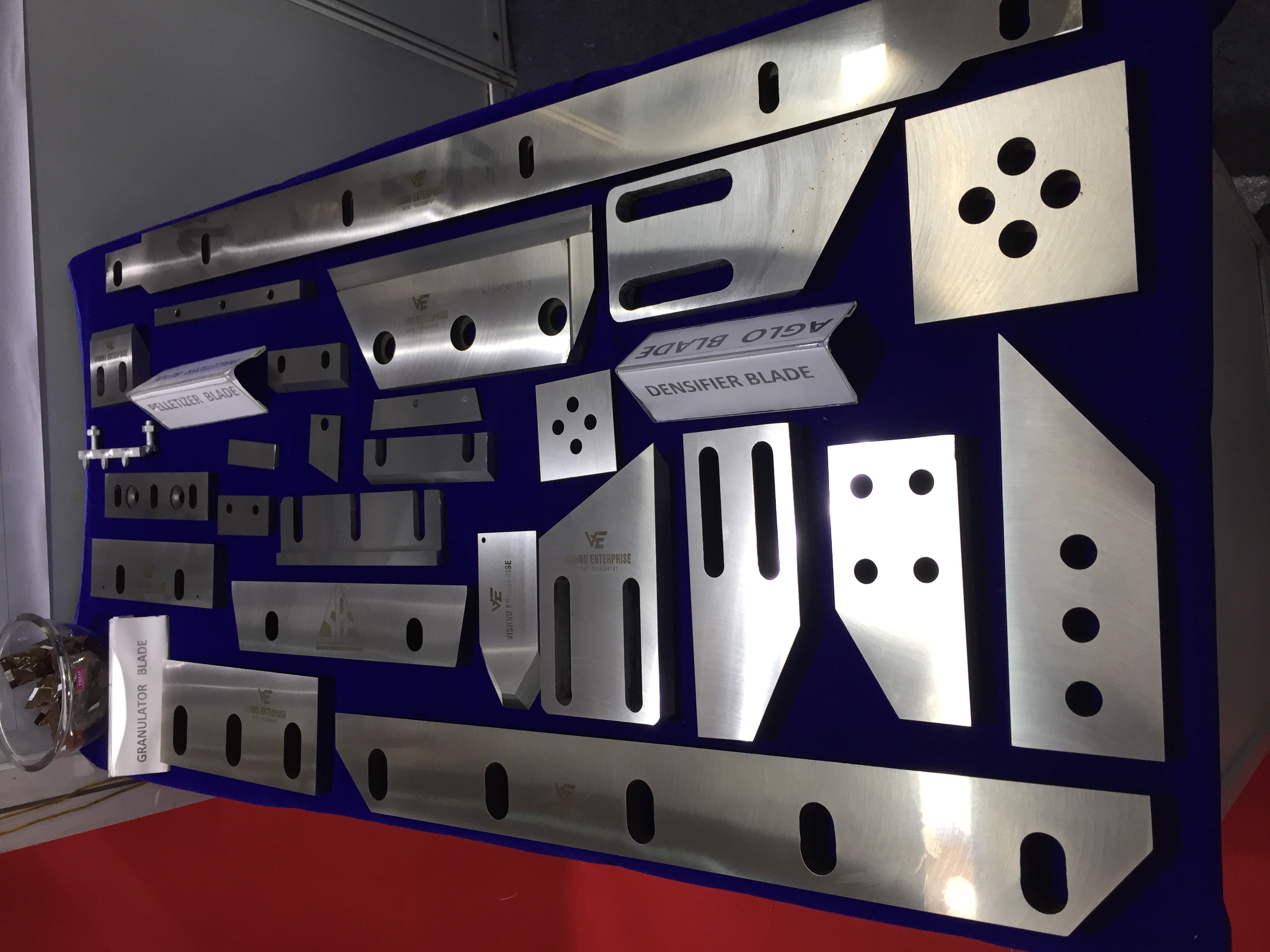

Agglomerator allloy blades

2000-10000 INR/Piece

Product Details:

- Features Wear-resistant, Durable, Long Life, Corrosion-resistant

- Shape Custom (As per agglomerator blade design)

- Operate Method Mechanical (powered by agglomerator drive)

- Hardness 58-62 HRC

- Operation Type Rotating/Shearing

- Coating Alloy Surface

- Cutting Capacity Heavy Duty

- Click to View more

X

Agglomerator allloy blades Price And Quantity

- 2000-10000 INR/Piece

- 20 , , Piece

Agglomerator allloy blades Product Specifications

- High Alloy Steel

- Agglomerator Machine

- Customized, typically 8-18

- Special Alloy/Surface Hardened

- 300-800 RPM (machine dependent)

- Agglomerator Blade

- Agglomeration & Cutting

- Custom (based on machine requirement)

- High Precision

- Mechanical (powered by agglomerator drive)

- 58-62 HRC

- Wear-resistant, Durable, Long Life, Corrosion-resistant

- Custom (As per agglomerator blade design)

- High

- Heavy Duty

- Industrial Grade

- Alloy Blade

- Alloy Surface

- Rotating/Shearing

Agglomerator allloy blades Trade Information

- 20 , , Piece Per Day

- 20 Days

Product Description

This blade are made from best alloy as D2 & D3 & hardenend & tempered in proper method to avoid krackness

This blade are used in aglomerator/ densifyier machine to Cut the big size polythene to small size so then it go to extruder & convert into granules & then to used for many purposes

Exceptional Durability and Precision

Manufactured with high-grade alloy steel and advanced surface hardening processes, our agglomerator blades ensure long-lasting service even under demanding industrial workloads. Their high hardness rating (58-62 HRC) and polished or matte finish options contribute to precise, efficient cutting capabilities and optimal corrosion resistance for aggressive recycling environments.

Customizable to Fit Your Machinery

Each blade can be customized in diameter (typically 8-18 mm), thickness, length, and shape to perfectly fit your agglomerator requirements. With bored or slotted mounting holes and optional edge types (straight or serrated), our blades are engineered to integrate seamlessly with most standard agglomerator machines, enhancing operational flexibility and efficiency.

FAQs of Agglomerator allloy blades:

Q: How do I select between a serrated or straight edge for the agglomerator alloy blade?

A: The choice between serrated and straight edge depends on your material type and desired cutting accuracy. Serrated edges excel at gripping and cutting tougher films or irregular waste, while straight edges offer cleaner cuts for finer flakes or uniform materials. We can recommend the optimal edge style based on your specific application.Q: What materials can these agglomerator blades process efficiently?

A: These blades are designed for plastics recycling, effectively handling films, waste fragments, and flakes from various polymer types. Their robust construction and coating enable high cutting force even in intensive agglomeration processes, delivering consistent results across diverse plastic materials.Q: When should I consider replacing my agglomerator blades?

A: Blades should be replaced when cutting performance drops, visible wear emerges, or cuts lose precision. Our blades are built for long service life under heavy use, but routine inspections and maintenance will help ensure continued efficiency and safety in your recycling operations.Q: Where are these alloy blades manufactured and supplied?

A: We design, manufacture, and supply agglomerator alloy blades from India, serving clients worldwide as exporters, manufacturers, service providers, and suppliers. Our blades comply with industrial standards and are widely compatible with agglomerator machines from leading global brands.Q: What is the process for customizing a blades dimensions and features?

A: Customization involves specifying your agglomerators model, required blade diameter (typically 8-18 mm), thickness (10-25 mm), length, mounting type, and edge preference. Our engineering team reviews these details to fabricate blades tailored for optimal machine performance and durability.Q: How do these blades benefit plastic recycling operations?

A: Our blades enhance recycling efficiency by delivering high precision cutting, exceptional durability, and resistance to high temperatures and corrosion. Their design supports heavy-duty, continuous processing, reducing downtime and operating costs for large-scale plastics recycling facilities.Q: What mounting options are available for these blades?

A: We offer bored and slotted mounting hole designs to accommodate various agglomerator machine configurations. This flexibility ensures proper fit and secure installation, maximizing safety and performance during high-speed rotational or shearing operations.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Industrial Cutting Blades' category

Sangeeta Enterprises

GST : 27ABHPJ1701B1ZD

GST : 27ABHPJ1701B1ZD

Plot No. 61, Kerawala Building, First Floor, Shop No. 7, Mangaldas Road, Lohar Chawl, Kalbadevi,Mumbai - 400002, Maharashtra, India

Phone :08045803812

|

Sangeeta Enterprises

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |