Densifier cutting blade

2000-10000 आईएनआर/टुकड़ा

उत्पाद विवरण:

- प्रचालन विधि Mechanized/Automatic

- काटने की सटीकता ±0.1 mm

- लेप करना Uncoated

- ब्लेड साइज Diameter 300 mm x Thickness 3 mm

- कोटिंग का प्रकार None

- लम्बाई Custom available

- टूल टाइप Blade

- अधिक देखने के लिए क्लिक करें

X

मूल्य और मात्रा

- टुकड़ा/टुकड़े

- 20

- टुकड़ा/टुकड़े

उत्पाद की विशेषताएं

- High

- Low to Medium

- Rotary Blade

- Suitable for plastic dense material

- Circular

- Cutting

- 300 mm

- Mechanized/Automatic

- ±0.1 mm

- Uncoated

- Diameter 300 mm x Thickness 3 mm

- None

- Custom available

- Blade

- Densifier / Plastic Recycling Machine

व्यापार सूचना

- प्रति दिन

- दिन

- ऑल इंडिया

उत्पाद वर्णन

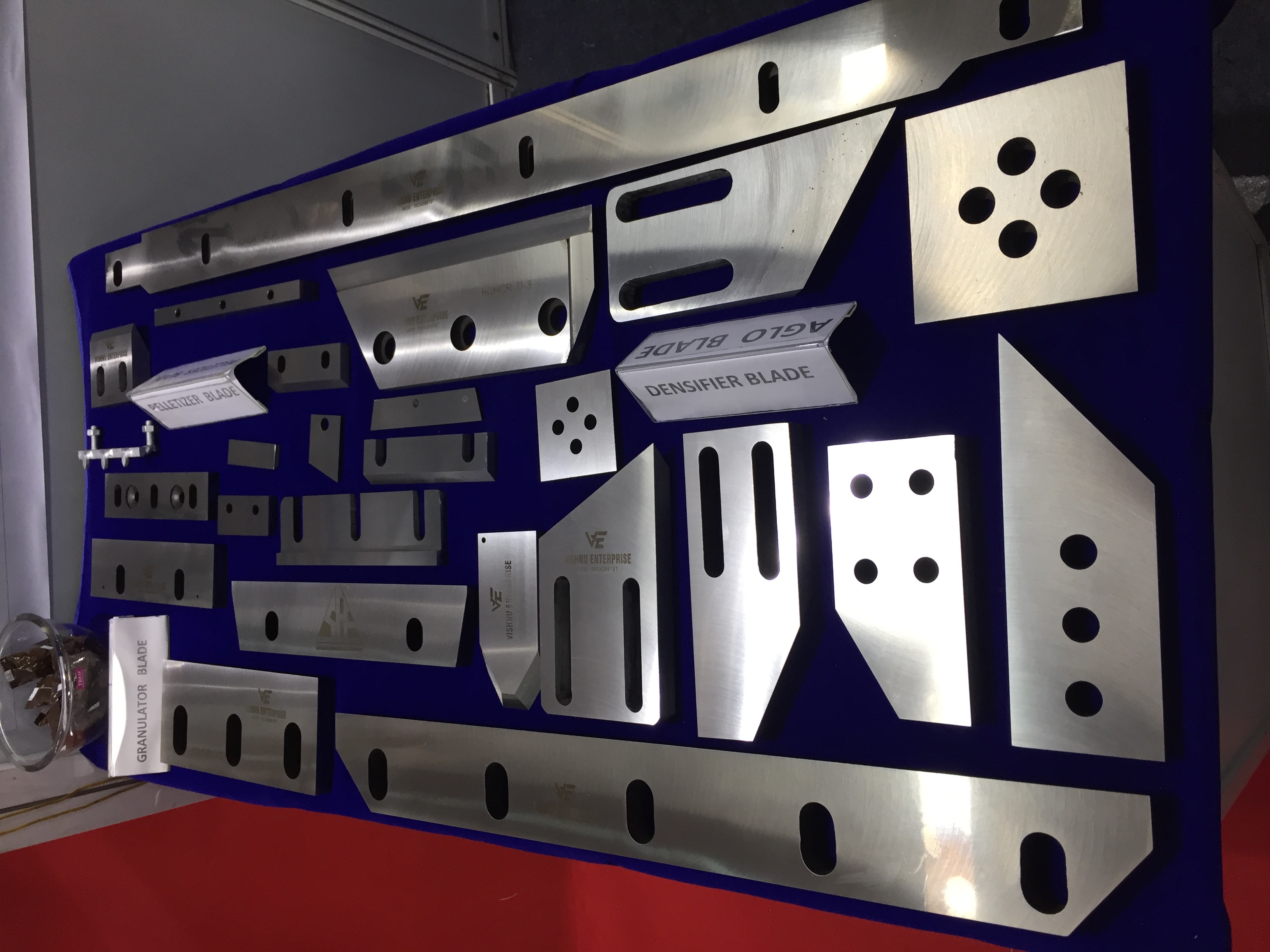

Blade Plastic Cutting

Plastic industries Blades

Plastic industries Blades

- We offer an extensive range of advance plastic processing blades for a wide variety of applications.

- We are manufacturing all kind of industrial blades used in plastic reprocessing industries.

- Agglomerator blade

- Granulator blade

- Mixer blade

- Pelletizers blade

- We also provide any kind of blades as per customer requirements.

- Made from best imported steel with suitable hardness.

- Made as per customer specification weather it is of Hard facing welding electrode , solid carbon tool steel, HCHCR steel & the inlaid tungsten carbide tip blades, essential for good cutting which reduces the machine load and enhances machine life.

- We use high quality electrodes in manufacturing of welded blades of superior quality

- Our blades are made of certified hardfacing welding which maintains required hardness & quality for cutting & retains a fine cutting edge for long time.

- All products are properly heat treated to give uniform hardness & maximum cutting performance.

- Precision grinding is done to exact point of tolerance as required.

- Testing and inspection is done at all stages of production to ensure that high standard is maintained.

- We are pleased to respond favorably to your genuine enquires

- Large range of granulator & palletiseing blades suitable for granulating, palletizing& dicing of plastic or manmade fibres.

- Correct balance of shock and wear resistance& excellent durability to ensure smooth operation which increases the cutting efficiency for all grades of polymers & elostomers

- Optimum hardness & toughness.

Engineered for High-Efficiency Recycling

This densifier cutting blade is precisely crafted for demanding plastic waste recycling tasks. Its robust high carbon steel material and heat resistance up to 150C ensure consistent performance even during prolonged use. The circular shape, combined with a choice between serrated or plain edges, enhances versatility and cutting capacity for dense plastic materials. Each blade is polished to reduce friction, which improves longevity and operation speed in mechanized or automatic machines.

Enhanced Safety and Long-Term Reliability

Operator safety is a prime consideration; the blade is carefully designed to minimize risks during all phases of operation. Its durable construction and compatibility with standard densifier cutter mountings provide a trouble-free installation process. With the option to resharpen the blade multiple times and a long operational lifespan when maintained under recommended parameters, this blade stands as a cost-effective and reliable component for exporters, manufacturers, and service providers.

FAQs of Densifier cutting blade:

Q: How does the densifier cutting blade contribute to efficient plastic recycling?

A: By providing precise and high-speed cutting for plastic waste in densifier machines, the blade optimizes the recycling process. Its sharp, robust edge allows it to process dense materials efficiently, improving throughput and reducing machine downtime.Q: What customization options are available for the densifier blade?

A: We offer customization in blade length and edge type (serrated or plain) to suit specific recycling requirements. Custom packaging is also available, and our team can assist in developing solutions tailored to your machine or plastic processing volume.Q: When should the blade be resharpened, and how many times is it possible?

A: The blade should be resharpened when you notice decreased cutting efficiency or increased force is needed. It is designed to withstand multiple resharpenings, extending its service life provided sharpening is done by a professional.Q: Where can the densifier cutting blade be installed?

A: It fits standard densifier cutter mountings typically found in plastic recycling densifier machines. Its compatibility supports seamless integration into existing recycling lines within factories or processing facilities.Q: What is the process for installing and maintaining the blade?

A: To install, match the blade to your machines cutter mounting specifications and ensure it is securely fastened. For maintenance, routinely check the blade for wear, promptly resharpen dull edges, and avoid exceeding the recommended operating temperature of 150C.Q: How does the blades heat resistance benefit continuous operation?

A: Thanks to its capability to withstand temperatures up to 150C, the blade can handle the intense friction generated during continuous, high-speed cutting, reducing the risk of deformation or premature wear during extended production cycles.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

Industrial Cutting Blades अन्य उत्पाद

संगीता इंटरप्राइजेज

GST : 27ABHPJ1701B1ZD

GST : 27ABHPJ1701B1ZD

प्लाट न. 61, करवाला बिल्डिंग, फर्स्ट फ्लोर, शॉप नो. 7, मंगलदास रोड, लोहार चावल, कालबादेवी,मुंबई - 400002, महाराष्ट्र, भारत

फ़ोन :08045803812

|

Sangeeta Enterprises

सर्वाधिकार सुरक्षित.(उपयोग की शर्तें) इन्फोकॉम नेटवर्क प्राइवेट लिमिटेड . द्वारा विकसित एवं प्रबंधित |